Avoiding Costly Mistakes: The Role of Packaging & Labeling in Pharma Compliance

20-Feb-2025

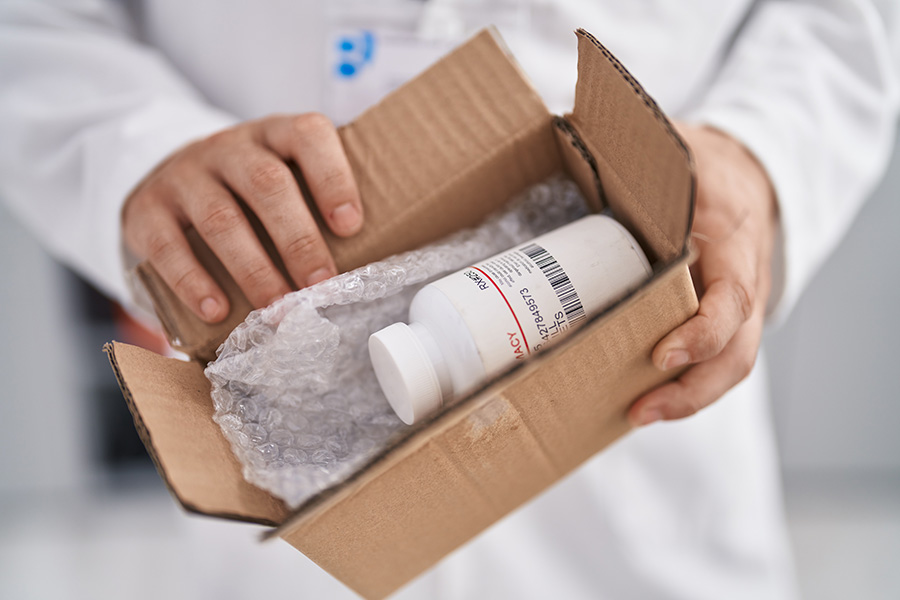

So much pharma regulation that one error can be disastrous. Fines, up to and including product recall, the cost is staggering. Perhaps most important, but most undervalued, in pharma compliance, however, is labelling and packaging. Labelling and packaging are not convenience or cosmetics; they are patient safety, regulatory compliance, and the cost of expensive mistakes. Let us talk about why packaging and labelling are so very much at the forefront of pharma compliance minds and how organizations can navigate through this dizzying landscape.

The Role of Labeling and Packaging for Pharma Compliance

Labelling and packaging are the initial points of contact in confirming that pharmaceutical products are being shipped successfully and safely to the consumer. Labelling and packaging also serve as a method of communication among producers, medical professionals, and patients. A correct label contains useful information in the form of dosage guidance, expiration date, and side effects. Packaging protects against tampering, contamination, and climate conditions. Good labelling and packaging can avoid errors that otherwise will have grave health consequences or juridical responsibility.

But labelling and package mistakes happen more often than they should. The wrong label, the wrongly read barcode, or an inferior package can precipitate regulatory offences, product recall, and possible risk to patients. Not dollar-costly, but reputation- and customer-trust-scarce as well. Pricey packaging and labeling mistakes then are the paramount concern of pharmaceutical companies.

Regulatory Requirements

Pharmaceutical companies have a global presence, and hence they have to adhere to the laws of many countries. Organizations such as the U.S. Food and Drug Administration (FDA), European Medicines Agency (EMA), etc. require very stringent labelling and packaging regulations. These are constantly changing because of threats and advancements in technology. The FDA's Drug Supply Chain Security Act (DSCSA) is one such example, which has certain labelling standards for the prevention of drug counterfeiting.

Violations of these regulations can lead to humongous fines, delays in product launches, or even revocation of manufacturing approval. To prevent million-dollar errors, pharmaceutical manufacturers have to stay current with evolving regulations and stay in sync with up-to-date packaging and labelling procedures. This encompasses proactive strategies through ongoing audits, employee training, and regulatory expertise consultations.

The Cost of Errors: Real-World Examples

The result of mispackaging and mislabeling can be disastrous. Consider the instance of a large pharma company that had to conduct a multi-million-dollar recall when there was a mistake in labelling. In the process of making two extremely similar-looking labels, they got confused and made erroneous dosage information on the pack. Not only did it cost the company money, but it also tainted the company and destroyed customer confidence.

The second situation is a packaging error that rendered a medicine non-sterile, leading to contamination and finally patient injury. The firm was forced to recall the whole batch, litigate, and shell out record-breaking fines. These actual instances read, Steer clear of expensive errors by staying away from expensive errors through strict packaging and labelling protocols.

Best Practices for Steering Clear of Costly Mistakes

Minimum possible mistakes should be avoided through best practices in labelling and packaging by pharmaceutical production firms. Such precious measures are the following:

- Invest in Quality Control: There should be proper quality control practices carried out at every stage of labelling and packaging procedures. These involve double verifications on the accuracy of labelling, precise scanning through bar codes, and periodical checking.

- Technology used: High-technology machinery such as automated labelling machines, barcode scanners, and electronic track-and-trace systems can elevate the degree of risk of error to an extremely high degree. The technology also leaves an electronic trail so that errors can be traced easily and corrected.

- Employee training: The most common cause of labelling and packaging errors is human error. Periodic training will most probably make employees realize that rules have to be obeyed and may instil in them the right kind of abilities to avoid making a mistake.

- Collaboration with Labeling and Packaging Specialists: Collaboration with labelling and packaging specialists is always beneficial. The specialists are familiar with regulatory information as well as industry standards. Specialists are also beneficial in package design to introduce functional as well as compliance requirements.

- Carry Out Periodic Audits: Periodic auditing of the labelling and packaging processes can help in the detection of whether there is any pending risk that is yet to be identified before it becomes a costly mistake. The audits should be thorough and cover every aspect of the supply chain.

Conclusion

To pharma companies, prevention of expensive mistakes is not dimes and pennies; it's maintaining reputations and keeping people healthy. Packaging and labelling help them to do so. They do it by remaining legal, remaining steadfast on quality authentication, employing technology tools wisely, and remaining compliant as a way of life. Therefore, pharma companies prevent losses, as by delivering effective products to consumers, they also remain away from danger.

No one can exaggerate the importance of pharma compliance labelling and packaging. It's a complicated but hugely important aspect of the business deserving of notice, precision, and regular innovations. With an intense emphasis on labelling and packaging, pharma companies can avoid expensive blunders and guarantee regulatory compliance commitment and patient safety. Where there is a mistake at a huge expense, precise labelling and packaging are not just best practices—they're obligatory.

Recent Posts

Impact of 2024 HCPCS Updates on Healthcare Providers

16-Aug-2024

The 2024 Guide to Employee Motivation

21-Aug-2024

7 Ways to Improve Performance Management at Your Company

23-Aug-2024

Choosing the Best HR Tool for Education: 5 Things You Need to Know

28-Aug-2024

Payroll Records: A Guide to Retention and Disposal

04-Sep-2024

AI Limitations Why Certain Jobs Will Always Require a Human Touch

09-Sep-2024

How the New HIPAA Rules Impact Reproductive Health Care Providers

13-Sep-2024

Best Strategies to Manage Toxic Employees and Boost Team Morale

20-Sep-2024

Top 7 Common Coding Errors That Trigger Audits and How to Prevent Them

26-Sep-2024

How OSHA is Involved in Mandating Protections for Employees

14-Oct-2024

FDA Software Classification Guidance

22-Oct-2024

Stay Ahead of FDA Inspections: Best Practices for Managing Form 483 Citations and Warning Letters

24-Oct-2024

Best Practices to Reduce Validation Effort and Costs

06-Nov-2024

Best Practices for Medical Device Software Validation and Risk Management

14-Nov-2024

Training Strategies to Comply with EEOC New Harassment Standards

14-Nov-2024

Guideline On Computerized Systems and Electronic Data in Clinical Trials

17-Dec-2024

What is Human Factor Engineering in Medical Terms?

17-Dec-2024

What is the Objective of Supervisor Training?

24-Dec-2024